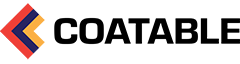

Features

DESCRIPTION: AUTO PREP is a single component solvent based primer for single-ply membranes. AUTO PREP promotes adhesion when applying STOP HEAT coating to tar/bitumen, plastic, TPO, PVC, Vinyl and EPDM. AUTO PREP seals surfaces while offering superior surface adhesion for all topcoats.

Characteristics:

- Easy to apply – airless, conventional or pump sprayer

- Promotes adhesion for tar, rubber, TPO or PVC materials

- Fast cure – 1 hour overcoat window at 70F (21C)

- Low VOC – 30 grams per liter

TYPICAL APPLICATIONS:

- Primer for STOP HEAT when applying over recreational vehicles (RV’s)

- Primer for STOP HEAT on sloped roofs with tar, rubber, TPO, or EPDM

SPREAD RATE: For new EPDM, PVC, TPO & Tar, AUTO PREP covers approximately 200 sq. ft. per gallon (18.5 sq. mtr/gallon) at 8 mils wet (200 microns wet), 1 mils dry (25 microns dry).

Technical Informations

SURFACE PREPARATION: All surfaces must be completely dry and free of loose rust, loose paint, visible moisture, dirt, mildew, oil, wax, chlorides, and any other contaminants that may affect adhesion or performance prior to applying AUTO PREP. Use a general degreaser if needed. Clean surface using simple green or a citrus cleaner to release dirt and degreaser residue. Power wash if possible @ 1500 psi, or scrub using heavy duty broom. If surface is contaminated with salts, use Chlor-Rid or equivalent as part of the power wash. AUTO PREP must be applied during proper temperatures listed below. Maximum surface temperature when applying is 180 F (82C). Minimum surface temperature when applying is 40F (5C). Maximum surface temperature after curing is 180F (82C).

APPLICATION INSTRUCTIONS: Do not shake the container. Stir thoroughly by hand for thirty seconds. Do not create a vortex when mixing. Use outdoors or in a well-ventilated area. Do not apply to surfaces that exceed 180F (82C). AUTO PREP must be applied to a dry surface as soon as possible after cleaning. It can be applied by conventional, airless or pump sprayers. Do not brush or roll. Airless machines need to spray at a minimum rate of one gallon per minute using a .007-.009 reversible tip, or a solvent ready hand pumped sprayer. Temperature must always be a minimum of 5 degrees above the dew point during application. Cure times are 60 minutes to tack free at 70F (21C). Overcoat times are 60 minutes at 70F (21C) at 40% relative humidity.

CLEAN UP: Remove any uncured coating by wiping a surface with MEK or comparable solvent. Follow solvent manufacturers directions. Freshly cured product is removed with sandpaper or wire brush. Gloves and safety glasses are always required during set up, application, and clean up. If spraying, keep solvent ready to clean equipment before any brake and conclusion of job.

SPREAD RATE: For new EPDM, PVC, TPO & Tar, AUTO PREP covers approximately 200 sq. ft. per gallon (18.5 sq. mtr/gallon) at 8 mils wet (200 microns wet), 1 mils dry (25 microns dry).

SEE SDS FOR ADDITIONAL INFORMATION.

KEEP OUT OF REACH OF CHILDREN.

FOR PROFESSIONAL USE ONLY.

Questions and Answers

-

What type of surfaces require AUTO PREP?

EPDM, PVC, Modified Bit and TPO

-

How many coats are needed?

1

-

Is AUTO PREP flammable?

Yes

-

What color is AUTO PREP?

Clear/Amber

-

When can I overcoat AUTO PREP?

1 hour when 70F & 40% humidity, if temperature is higher it tends to set up faster, and slower if colder. Must apply a topcoat within 48 hours @ 70 humidity.

-

Can I walk over AUTO PREP after applying?

Only after its dry to touch, because it remains slightly tacky. Caution its very slippery when wet.

-

Minimum temperature for applying?

40F

-

Maximum surface temp when applying?

180F, note on hot roofs, coating may set up faster than 1 hour.

-

How do you clean AUTO PREP?

Acetone or solvent (xylene)

-

How to apply AUTO PREP?

Airless spray ½ gallon per minute or HVLP sprayer or electric pump sprayer, or brush and roller. It has the consistency of mineral spirits.

-

What is the spread rate?

200 ft2 per gallon

-

What type of personnel protection should I use when applying AUTO PREP?

Use appropriate PPE including NIOSH approved respirator, safety glasses and gloves when applying AUTO PREP.

-

What is recommended Surface Preparation?

Surface must be clean from oil, tar, rust, grease, salts, dirt and films.

For RV’s and Roofing use either a 1,500 psi power wash or scrub with heavy duty broom and laundry

detergent or dawn dish soap or citrus cleaner (Simple Green) to remove oil residue.

Surface must be completely dry when applying. -

What if it rains after applying AUTO PREP?

As a solvent you will get adhesion very quickly, and as long as its not pouring rain for at least 4 hours you should be ok.

-

How many components?

Single component

-

How long do I mix by hand?

1 minute

-

Storage temperature and shelf life?

Above 40F and below 100F, two years shelf life.